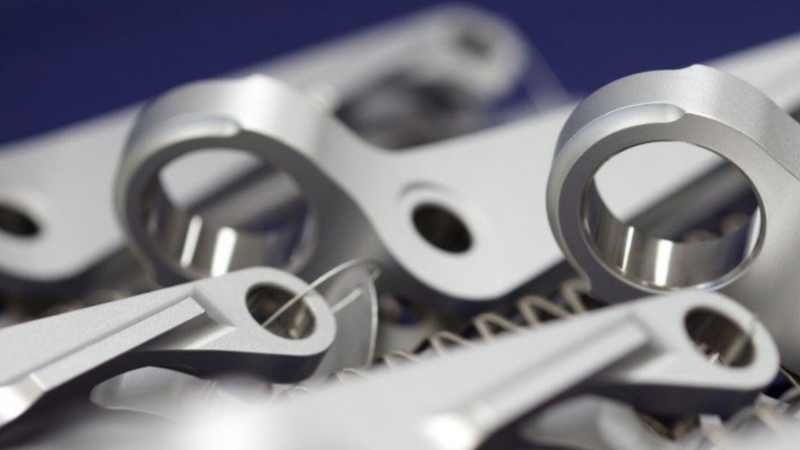

On average, about 2000 fasteners are installed in a common passenger car. They are often invisible but always essential. Screws and nuts hold car or other machinery components together, they have to resist extreme environmental impacts and guarantee a smooth and safe driving experience.

Of course, it's not only vehicles where fasteners are essential. In fact, the industry is also strongly tied to the production of aircrafts, appliances, agricultural machinery, commercial construction, and infrastructure. More than 200 billion fasteners are used per year in the U.S., 26 billion of these by the automotive industry.

With the rise of the e-mobility sector, fasteners gained further importance in the construction of battery packs.

SurTec, as a supplier for tailor-made chemical specialities, is unique in the field of surface treatment for fasteners offering solutions along the entire process chain:

SurTec's electroplating processes include every step from the pre-treatment, solutions for zinc and zinc alloys to top coats and sealers.

With the acquisition of the brand precote® in December 2022, SurTec further broadened it's competencies in the fastener industry. With the precote® product range now being part of the SurTec portfolio, the company serves a wide variety of applications worldwide in the field of thread locking and sealing, for example in the automotive industry, e-mobility, mechanical engineering, the aerospace industry, household appliances and other industries.

By choosing SurTec as their chemical supplier customers benefit from a broad range of profound expertise, excellent service, global contacts and high-quality products - everything from a single source.